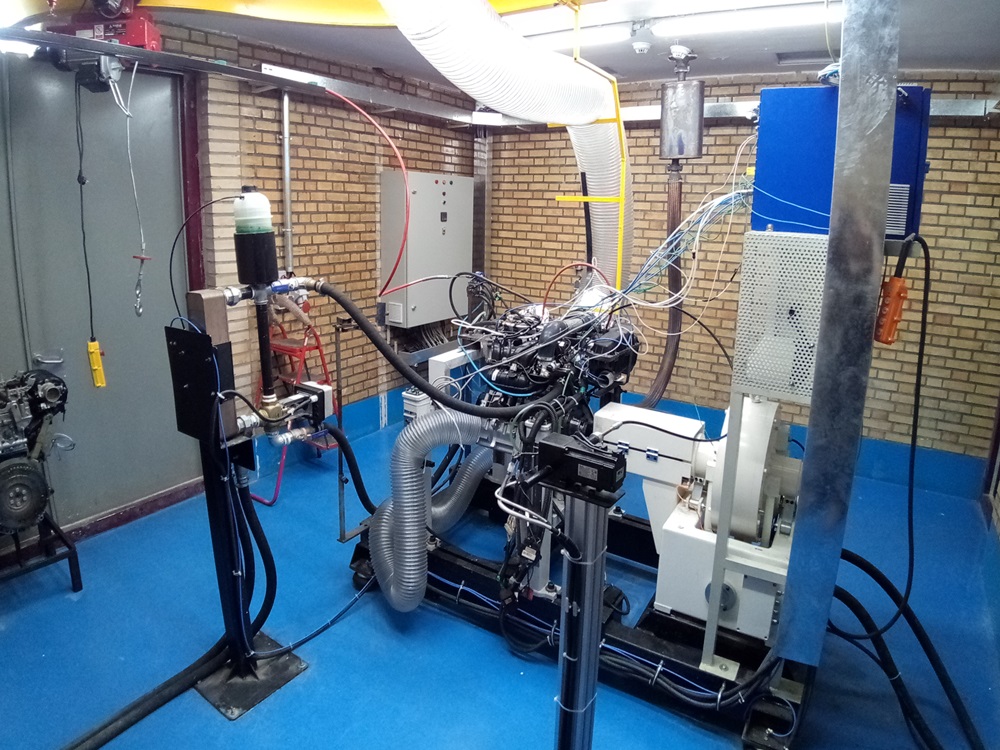

Based on technical knowledge and cooperation with advanced engine laboratories, Besapars Sanat motor laboratory is able to perform many engine validation tests. These tests include durability, performance, duty, combustion and engine mapping tests.

In the durability tests, the ability and performance of the engine or any of the systems are evaluated for its useful life in different conditions under thermal and mechanical loads, and after the test is completed, the engine parts are rated. takes These tests are done after the duty tests. Some of the motor durability tests applicable in the motor laboratory are:

• Dynamic 500 hour test: It is suitable for developing parts and testing them in more difficult conditions in transient states. This test is designed based on the high frequency failure theory.

• Standard 200 hour test: It is suitable for quick identification of major friction problems, critical parts and wear.

• 110 hours critical speed test: This test is performed to validate the movement systems of valves and sliding cranks in dynamic and critical conditions

In the maximum performance test, the ability of the engine is checked in the state of fully open throttle at different rotational speeds. The important indicators of this test are:

• Engine power and torque

• Fuel consumption

• Blow-by gases from the crankcase

• Amount of additional air (Lambda)